Founded In

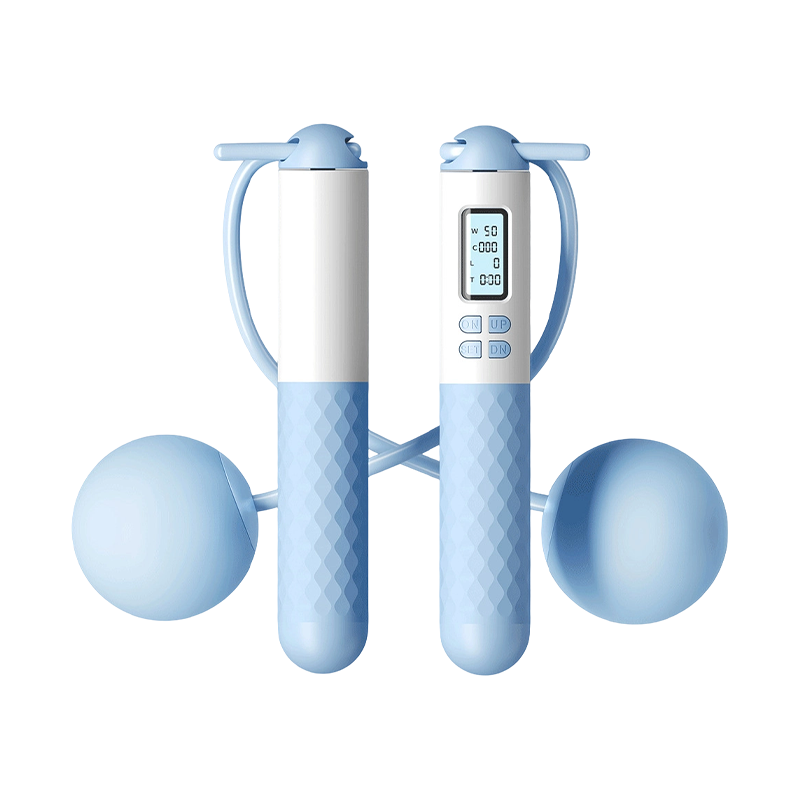

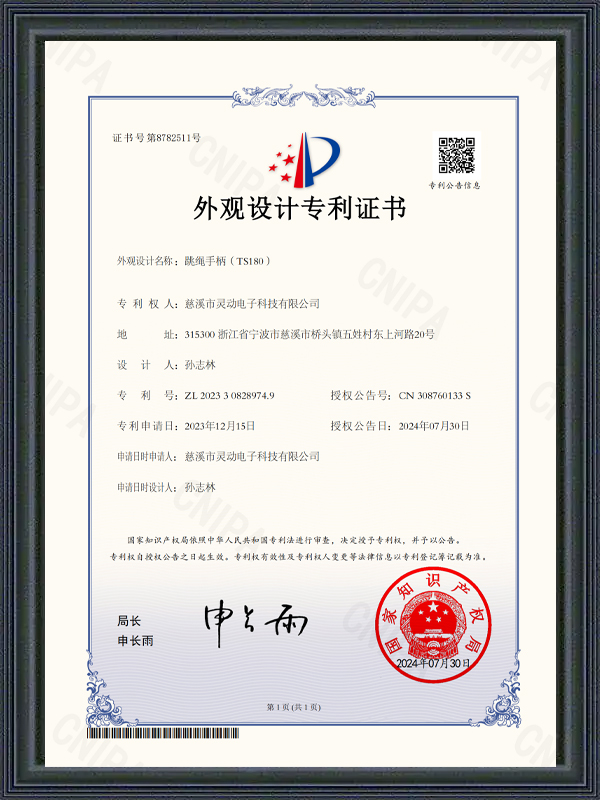

Cixi Lingdong Electronic Technology Co., Ltd. is China Plastic Handle Racing Jump Rope Suppliers and Plastic Handle Racing Jump Rope Manufacturers .And it was established in May 2012, located in Qiaotou Town of Cixi City, the hometown of Autumn rain of Ningbo City, Zhejiang Province, adjacent to G92 Hang-Ningbo Highway and G15 Shen-hai Highway, facing Shanghai across the sea, at the south end of Hangzhou Bay Bridge. It is a professional sports and outdoor products manufacturer composed of professional managers, technicians and production personnel. To product development, mold manufacturing, injection molding, finished product assembly as one of the process service customers.

-

0

-

0㎡

Factory Area

-

0+

Employee Count

-

Fundamental Role of Handle Weight in Swing Dynamics — In an Electronic Counting Jump Rope, the handles are not merely support structures; they are integral to the rope’s rotational mechanics and overall user control. The distribution of weight along the handle directly affects ...

READ MORE -

Enhanced Grip Comfort for Extended Training: The Sponge Handle Jump Rope provides a soft, ergonomic grip that conforms to the natural shape of the hand, allowing users to maintain longer, uninterrupted training sessions without experiencing hand fatigue, blistering, or discomfo...

READ MORE -

Ergonomic Handle Shape and Contouring: The Sponge Handle Jump Rope features handles specifically contoured to fit the natural curvature of the human hand, providing an intuitive and secure grip for users with varying hand sizes. The handles are often slightly tapered or cylindr...

READ MORE

Durability and Wear of Plastic Handle Racing Jump Ropes

Material Characteristics of Plastic Handles

Plastic handles are widely used in racing jump ropes due to their affordability, lightweight properties, and ease of molding into ergonomic shapes. The choice of plastic material, such as ABS or polypropylene, affects both durability and resistance to wear. Cixi Lingdong Electronic Technology Co., Ltd., which provides integrated services including product development, mold manufacturing, injection molding, and assembly, focuses on selecting high-quality plastics that maintain structural integrity under repeated stress. Proper material selection ensures that the handles resist cracking or deformation even during intensive training, supporting consistent performance over time.

Manufacturing Processes and Structural Reinforcement

The injection molding process is critical in determining the strength and longevity of plastic handles. Precision molds and controlled molding parameters reduce the presence of weak points or thin areas that could lead to breakage. Additionally, some designs incorporate internal reinforcements or ribbing to enhance structural rigidity without increasing overall weight. By combining precise molding techniques with careful assembly, Cixi Lingdong Electronic Technology Co., Ltd. ensures that plastic handles maintain durability and resist wear even after prolonged use. Reinforced handles are less prone to cracking, bending, or developing surface imperfections during repeated impact.

Wear Resistance and Surface Quality

Surface wear is another important factor affecting plastic handle performance. Frequent gripping and rotation can lead to abrasion, especially when hands are sweaty or the jump rope is used on rough surfaces. Surface texturing, coatings, and ergonomic shaping help maintain grip stability while reducing localized wear. Cixi Lingdong Electronic Technology Co., Ltd. integrates these features into their product designs to ensure that handles retain their functional texture and smooth operation over time. Regular use does not significantly degrade the surface, providing consistent comfort and grip for the user.

Connection Points Between Handle and Rope

The interface between the plastic handle and the rope is subjected to repeated rotational stress and impact. Poorly designed connectors or weak attachments can lead to premature loosening or breakage. Cixi Lingdong Electronic Technology Co., Ltd. addresses this challenge by employing reinforced swivel joints, precision-fitted bearings, or molded connection points that distribute mechanical stress evenly. This reduces the likelihood of damage at the connection interface, helping both the handle and the rope maintain durability and smooth rotation over time.

Factors Influencing Breakage and Wear

Several factors affect the potential for plastic handle breakage or wear. Environmental exposure, such as extreme temperatures, humidity, or UV light, can weaken plastic over time. High-intensity or frequent training may increase mechanical stress, accelerating wear at gripping points or connection interfaces. Proper material selection, structural reinforcement, and surface treatments mitigate these factors. Cixi Lingdong Electronic Technology Co., Ltd. applies quality control throughout manufacturing to ensure handles maintain consistent performance despite variations in usage or conditions.

| Component | Primary Concern | Design or Material Solution |

|---|---|---|

| Handle Body | Cracking or bending | High-quality ABS or polypropylene with reinforced molding |

| Surface | Wear and abrasion | Textured or coated surfaces for grip stability |

| Rope Connection | Loosening or stress points | Swivel joints, reinforced connectors, precision molding |

Maintenance Practices to Enhance Longevity

Proper maintenance extends the lifespan of plastic handle racing jump ropes. Keeping the handles clean and dry prevents degradation of surface texture and reduces friction-related wear. Avoiding exposure to harsh chemicals or extreme environmental conditions helps preserve structural integrity. Users should also store the jump rope properly, avoiding excessive bending or compression of the handles. By following these practices alongside durable material and design choices, the handles can remain functional and resistant to breakage or wear over time.

Design Considerations for Consistent Performance

Plastic handle racing jump ropes are designed to balance weight, durability, and ergonomic comfort. Manufacturers like Cixi Lingdong Electronic Technology Co., Ltd. combine high-quality plastic materials, reinforced molding, ergonomic shaping, and durable connection points to produce handles that maintain performance under repeated use. These integrated design strategies reduce the risk of breakage, minimize wear, and ensure that the jump rope continues to provide reliable training support for both casual users and athletes.

Swivel Bearing Design and Maintenance in Plastic Handle Racing Jump Ropes

Swivel Bearing Function and Importance

The swivel bearing in a plastic handle racing jump rope is a critical component that allows smooth rotation of the rope while minimizing twisting and tangling. This rotation is essential for consistent performance during high-speed or repetitive training sessions. Manufacturers like Cixi Lingdong Electronic Technology Co., Ltd., which integrate product development, mold manufacturing, injection molding, and finished product assembly, focus on designing swivel bearings that are durable, reliable, and capable of withstanding repeated mechanical stress. The quality of the swivel bearing directly affects the user’s control, rope speed, and overall training experience.

Removability of Swivel Bearings

Some swivel bearings are designed to be removable, allowing users or technicians to replace or upgrade the component if necessary. This feature enhances the long-term usability of the jump rope by extending the lifespan of both the handle and rope assembly. Removable bearings typically fit into precision-molded housings within the handle, ensuring a secure connection while still allowing for disassembly. Cixi Lingdong Electronic Technology Co., Ltd. applies high-precision molding and assembly techniques to produce handles that accommodate removable swivel bearings without compromising structural integrity or grip stability.

Maintainability of Swivel Bearings

Maintainable swivel bearings allow for periodic cleaning and inspection to prevent buildup of dirt, sweat, or debris, which could hinder smooth rotation. Maintenance can include wiping down surfaces, checking for wear, and ensuring proper alignment within the handle housing. By designing handles that facilitate access to the bearing, manufacturers like Cixi Lingdong Electronic Technology Co., Ltd. enable users to sustain performance and prevent premature wear. Proper maintenance extends the functional life of the bearing and supports consistent jump rope operation over extended periods.

Lubrication of Swivel Bearings

Lubrication is an important aspect of bearing performance, reducing friction and wear while maintaining smooth rotation. Some swivel bearings come pre-lubricated with long-lasting grease, while others allow for reapplication of lubricant during maintenance. Cixi Lingdong Electronic Technology Co., Ltd. integrates lubrication considerations during the design and assembly process to ensure the bearing maintains low friction and rotational stability. Regular lubrication, when applicable, contributes to extended bearing life, consistent rotation, and reduced mechanical noise during use.

Durability and Material Considerations

The materials used for swivel bearings, such as stainless steel, brass, or high-strength polymers, influence their durability and resistance to corrosion or wear. Cixi Lingdong Electronic Technology Co., Ltd. selects materials that combine smooth rotational performance with structural integrity, ensuring that bearings withstand repeated impact and rotational stress. Reinforced housing designs in the plastic handle prevent deformation and help maintain alignment, supporting both removable and maintainable features. These material choices are critical to sustaining performance over time, even with frequent or intense training.

| Feature | Purpose | Implementation |

|---|---|---|

| Removable Bearing | Allow replacement or upgrades | Precision-molded handle housing for secure fit and disassembly |

| Maintainable Bearing | Enable cleaning and inspection | Accessible handle design and proper alignment |

| Lubricated Bearing | Reduce friction and wear | Pre-applied grease or lubrication port for maintenance |

| Durable Materials | Ensure long-term structural integrity | High-strength polymers, stainless steel, or brass components |

Integration with Rope and Handle Performance

Swivel bearings are integrated with the rope and handle design to ensure balanced rotation and ergonomic performance. Proper alignment, lubrication, and secure housing contribute to smooth rope motion and consistent training feedback. Cixi Lingdong Electronic Technology Co., Ltd. considers the entire handle and rope system when designing bearings, ensuring that the components work harmoniously to provide effective speed, control, and comfort for the user. This integrated approach reduces the likelihood of twisting, tangling, or mechanical failure during high-intensity use.

Maintenance Recommendations

Users can prolong the functional life of swivel bearings by following recommended maintenance practices. Regular inspection for wear, occasional cleaning to remove debris, and lubrication when applicable help maintain smooth rotation and prevent performance degradation. Removable and maintainable bearings allow for easy servicing, supporting long-term usability. By combining durable materials, precise assembly, and accessible maintenance features, Cixi Lingdong Electronic Technology Co., Ltd. ensures that swivel bearings remain reliable components within plastic handle racing jump ropes, enhancing both performance and user satisfaction.

English

English Español

Español عربى

عربى