Founded In

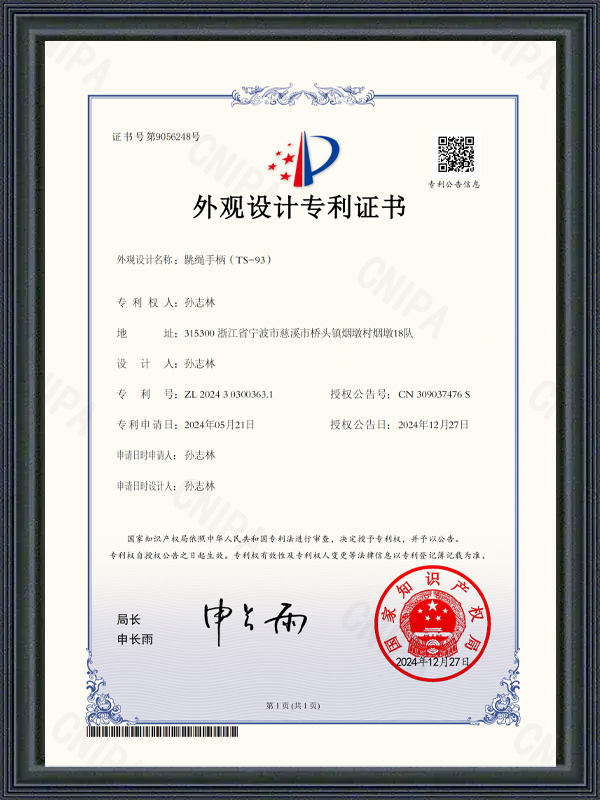

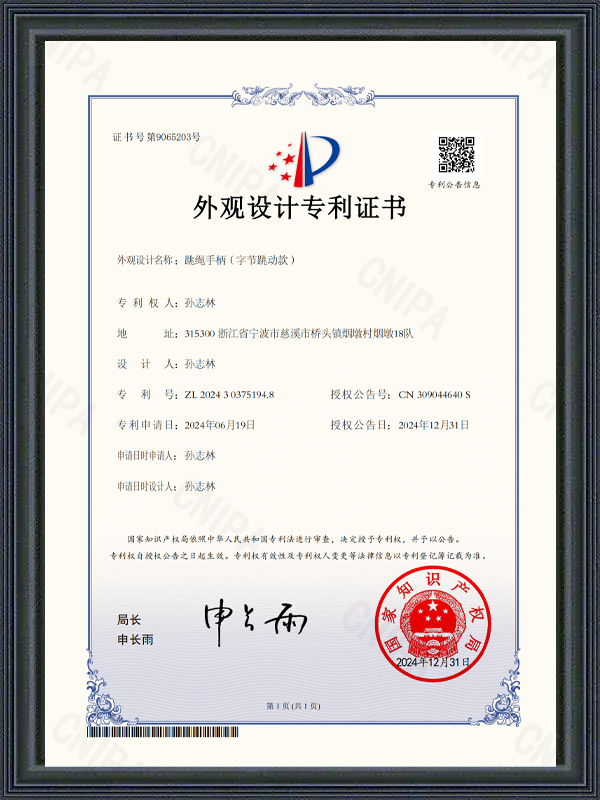

Cixi Lingdong Electronic Technology Co., Ltd. is China Smart Counting Jump Rope Suppliers and Smart Counting Jump Rope Manufacturers .And it was established in May 2012, located in Qiaotou Town of Cixi City, the hometown of Autumn rain of Ningbo City, Zhejiang Province, adjacent to G92 Hang-Ningbo Highway and G15 Shen-hai Highway, facing Shanghai across the sea, at the south end of Hangzhou Bay Bridge. It is a professional sports and outdoor products manufacturer composed of professional managers, technicians and production personnel. To product development, mold manufacturing, injection molding, finished product assembly as one of the process service customers.

-

0

-

0㎡

Factory Area

-

0+

Employee Count

-

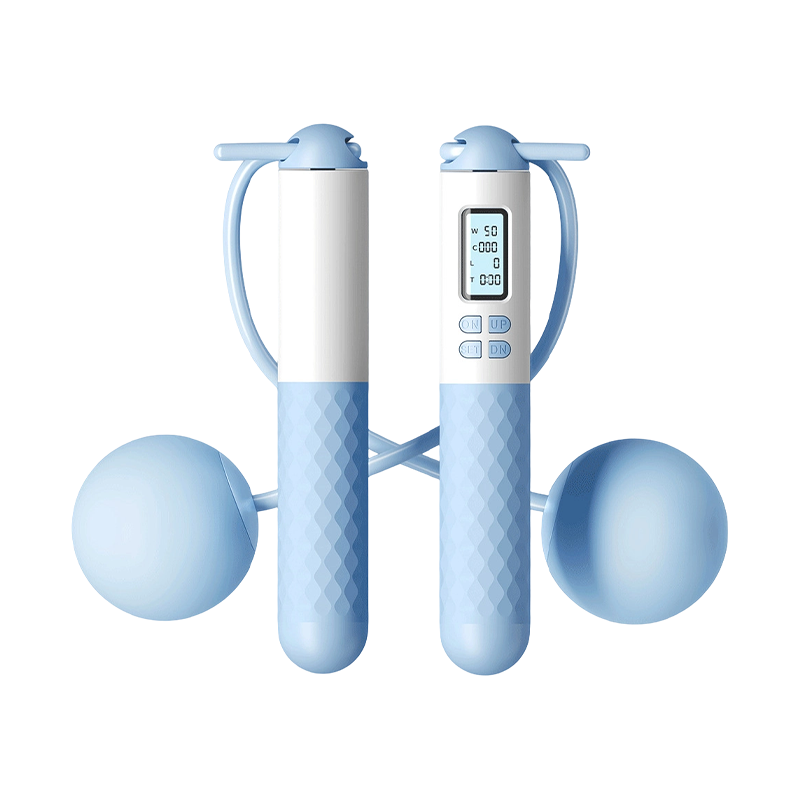

Fundamental Role of Handle Weight in Swing Dynamics — In an Electronic Counting Jump Rope, the handles are not merely support structures; they are integral to the rope’s rotational mechanics and overall user control. The distribution of weight along the handle directly affects ...

READ MORE -

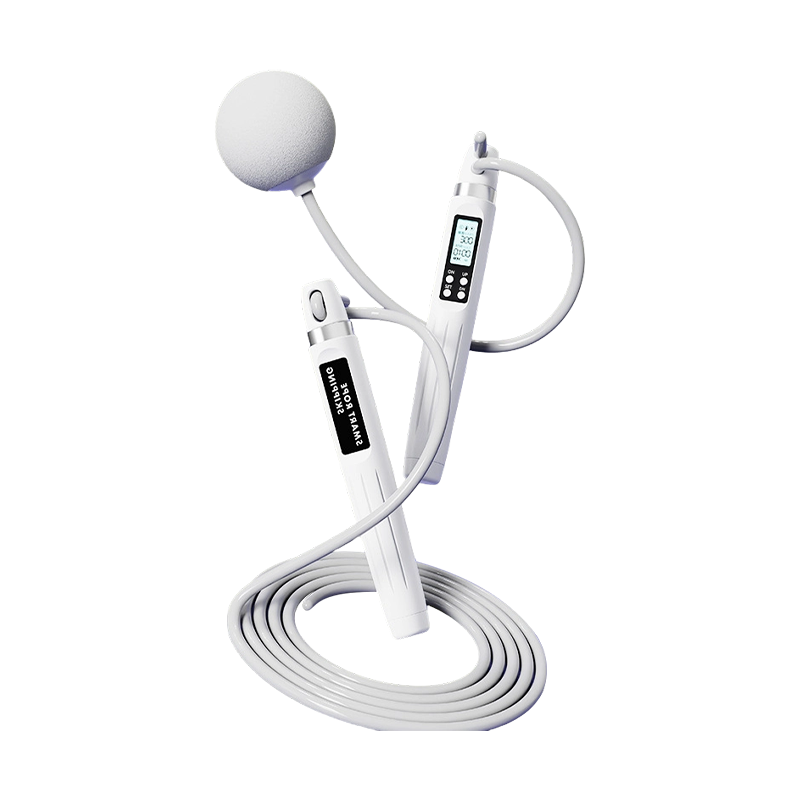

Enhanced Grip Comfort for Extended Training: The Sponge Handle Jump Rope provides a soft, ergonomic grip that conforms to the natural shape of the hand, allowing users to maintain longer, uninterrupted training sessions without experiencing hand fatigue, blistering, or discomfo...

READ MORE -

Ergonomic Handle Shape and Contouring: The Sponge Handle Jump Rope features handles specifically contoured to fit the natural curvature of the human hand, providing an intuitive and secure grip for users with varying hand sizes. The handles are often slightly tapered or cylindr...

READ MORE

Lifespan and Durability of Smart Counting Jump Rope Components

Smart Module Longevity

The smart module is the core of a smart counting jump rope, responsible for detecting rope rotations, calculating jump counts, and tracking additional metrics such as calories or workout duration. Its durability largely depends on the quality of the electronic components, the integrity of the soldering, and the protective casing that shields the module from mechanical impact, sweat, and moisture. Manufacturers like Cixi Lingdong Electronic Technology Co., Ltd., which integrate product development, mold manufacturing, injection molding, and assembly, ensure that smart modules are built with stable microcontrollers and high-quality PCBs. Protective housings, often made from reinforced polymers, help reduce the risk of damage during regular training sessions. With careful design and assembly, the smart module can remain reliable for several years under normal use, providing consistent performance and accurate counting for extended periods.

Battery Performance and Lifespan

The battery is a key factor in the continuous functionality of a smart counting jump rope. Rechargeable lithium-ion or lithium-polymer batteries are commonly used due to their stable energy density and reliable charge-discharge cycles. The lifespan of these batteries depends on usage frequency, charging practices, and environmental conditions. Repeated charge cycles gradually reduce maximum capacity, but careful design and assembly mitigate rapid deterioration. Proper integration ensures that battery compartments are secure, minimizing the risk of short circuits or energy loss. With typical household or gym usage, batteries can last for hundreds of full charge cycles, often providing dependable operation for two to four years, depending on user habits and charging consistency.

Display Durability and Visibility

The display, whether LED or LCD, provides essential real-time feedback on metrics such as jump count, time, or calories burned. Display longevity depends on the quality of the screen materials, protective layers, and assembly integration with the smart module. Protective coatings and secure embedding of electronic components prevent scratches, moisture ingress, and mechanical shocks. Cixi Lingdong Electronic Technology Co., Ltd. ensures precise assembly that maintains display visibility and accuracy even under extended use. When properly maintained, displays can remain clear and functional for several years, supporting long-term use alongside the smart module and battery.

Factors Influencing Component Lifespan

The lifespan of the smart module, battery, and display is affected by environmental conditions, usage patterns, and handling. Exposure to extreme temperatures, humidity, or accidental impacts can reduce component durability. Frequent or high-intensity use may increase wear on mechanical parts, while improper storage or charging can shorten battery life. To address these factors, manufacturers optimize material selection, protective housing, and assembly quality. Reinforced casing, moisture-resistant coatings, and secure electrical connections help minimize the effects of environmental and mechanical stress, supporting reliable performance over time.

Testing and Quality Assessment

Electronic counting jump ropes undergo various tests to ensure the longevity of their components. Functional testing of the smart module includes repeated jump simulations and sensor calibration to verify accuracy. Battery performance is assessed through charge-discharge cycle testing and temperature stress tests to evaluate energy stability. Displays undergo scratch resistance and impact testing to ensure clarity and durability. These evaluations help manufacturers identify areas for design improvement and confirm that the product can maintain performance under expected conditions of use.

| Component | Primary Durability Factors | Expected Lifespan |

|---|---|---|

| Smart Module | Quality of PCB, microcontroller, protective casing | 3–5 years |

| Battery | Charge cycles, environmental conditions, energy management | 2–4 years |

| Display | Screen material, protective layers, assembly quality | 3–5 years |

Maintenance Practices to Extend Lifespan

Proper maintenance is important to maximize the lifespan of all electronic counting jump rope components. Users should avoid exposing the device to extreme temperatures, keep the jump rope dry, and follow recommended charging practices. Regular cleaning and inspection of the smart module, battery compartment, and display help identify potential issues early. By adhering to these practices, users can maintain consistent performance, preserve battery capacity, and ensure display clarity over the long term, enhancing the overall usability and reliability of the smart counting jump rope.

Integration of Durability and User Experience

The smart module, battery, and display are designed to work seamlessly together while maintaining ergonomic balance and usability. Proper integration ensures that the weight, handle design, and electronic components do not compromise the jump rope’s performance or user comfort. Accurate counting, reliable power, and clear display functionality support effective training routines. By combining durable electronic components with ergonomic design and careful assembly, manufacturers like Cixi Lingdong Electronic Technology Co., Ltd. provide a smart counting jump rope capable of long-term, consistent performance across diverse training scenarios.

Durability and Wear of Smart Counting Jump Rope Handles and Rope

Handle Material and Construction

The handles of a smart counting jump rope are critical for both user comfort and performance. They must maintain a secure grip, resist wear, and support the electronic components inside. Manufacturers like Cixi Lingdong Electronic Technology Co., Ltd., which integrate product development, mold manufacturing, injection molding, and finished product assembly, focus on producing handles from high-quality polymers that combine durability with ergonomic design. The handle construction often includes reinforced cores or inserts to prevent deformation over time. Properly designed and assembled handles are less likely to loosen or develop structural weaknesses even after extended use. The careful selection of material and the precision of the molding process contribute to long-term stability, ensuring that the handles remain functional and comfortable during repeated training sessions.

Rope Material and Wear Resistance

The rope itself is a key factor in the long-term usability of a smart counting jump rope. Ropes are typically made from durable materials such as PVC, coated steel wire, or braided fibers, which are selected for their resistance to abrasion, kinking, and deformation. Cixi Lingdong Electronic Technology Co., Ltd. emphasizes precise manufacturing processes, including quality extrusion and coating, to produce ropes that maintain flexibility while withstanding repeated impact and rotation. A well-designed rope resists fraying, retains its smooth rotation through the handles, and minimizes tension loss, all of which are critical for consistent jump rope performance over time.

Connection Points Between Handles and Rope

The points where the rope connects to the handles are subject to significant mechanical stress. Loosening or wear at these connection points can compromise performance and durability. Companies like Cixi Lingdong Electronic Technology Co., Ltd. implement secure attachment mechanisms, such as reinforced swivels, bearings, or molded connectors, to reduce the risk of disconnection or excessive wear. Properly engineered connection points distribute rotational stress evenly, preventing premature loosening while maintaining smooth motion. This structural consideration ensures that both the rope and handles continue to function reliably even after prolonged use.

Factors Influencing Wear Over Time

Several factors affect the likelihood of wear or loosening in smart counting jump ropes. Frequent and high-intensity use increases mechanical stress on the rope and handles. Environmental conditions such as moisture, temperature changes, or exposure to abrasive surfaces may also impact material integrity. Proper material selection, ergonomic design, and manufacturing quality play key roles in mitigating these effects. Cixi Lingdong Electronic Technology Co., Ltd. employs precise molding, assembly, and material reinforcement to enhance resistance to wear and maintain structural integrity under typical training conditions.

Testing for Long-Term Durability

To evaluate potential wear and loosening, smart counting jump ropes undergo a series of tests. Handle durability tests simulate repeated gripping and twisting to assess material resilience and ergonomic stability. Rope abrasion and tensile tests measure resistance to surface wear, stretching, and kinking. Connection point stress tests evaluate how well the rope and handle interface withstand rotational forces. These testing protocols allow manufacturers to identify weak points and refine design elements. They ensure that products meet expected performance standards over prolonged use.

| Component | Testing Method | Observed Outcome |

|---|---|---|

| Handles | Grip and torsion simulation | Handles maintain ergonomic shape and grip stability |

| Rope | Abrasion and tensile tests | Rope retains flexibility and resists fraying |

| Connection Points | Rotational stress and bearing tests | Swivels and connectors maintain secure attachment |

Material Selection for Longevity

Choosing appropriate materials for handles and ropes is essential to minimize wear. High-quality polymers for handles provide structural rigidity while remaining comfortable, and coated or braided rope materials reduce friction and abrasion. The combination of durable polymers, reinforced connectors, and smooth rope surfaces helps prevent loosening or degradation during repeated use. The integration of material choice with precise injection molding and assembly ensures consistent performance across multiple production batches.

User Practices Impacting Durability

Even with high-quality manufacturing, user practices influence the longevity of smart counting jump ropes. Proper storage, avoiding over-rotation or harsh surfaces, and maintaining clean handles and ropes can reduce wear. Users should avoid excessive tension or abrupt impact that could stress the connection points or cause premature rope fraying. Following these practices in combination with well-designed products supports sustained usability and reliable performance over time.

Design Considerations for Consistent Performance

Manufacturers like Cixi Lingdong Electronic Technology Co., Ltd. combine material quality, ergonomic handle design, reinforced connection points, and durable rope construction to achieve long-lasting performance. These design considerations ensure that the handles remain firmly attached and retain their grip quality, while the rope maintains flexibility and smooth rotation. The integrated approach to product development, mold manufacturing, injection molding, and assembly provides a smart counting jump rope that can endure repeated use without significant loosening or wear.

English

English Español

Español عربى

عربى